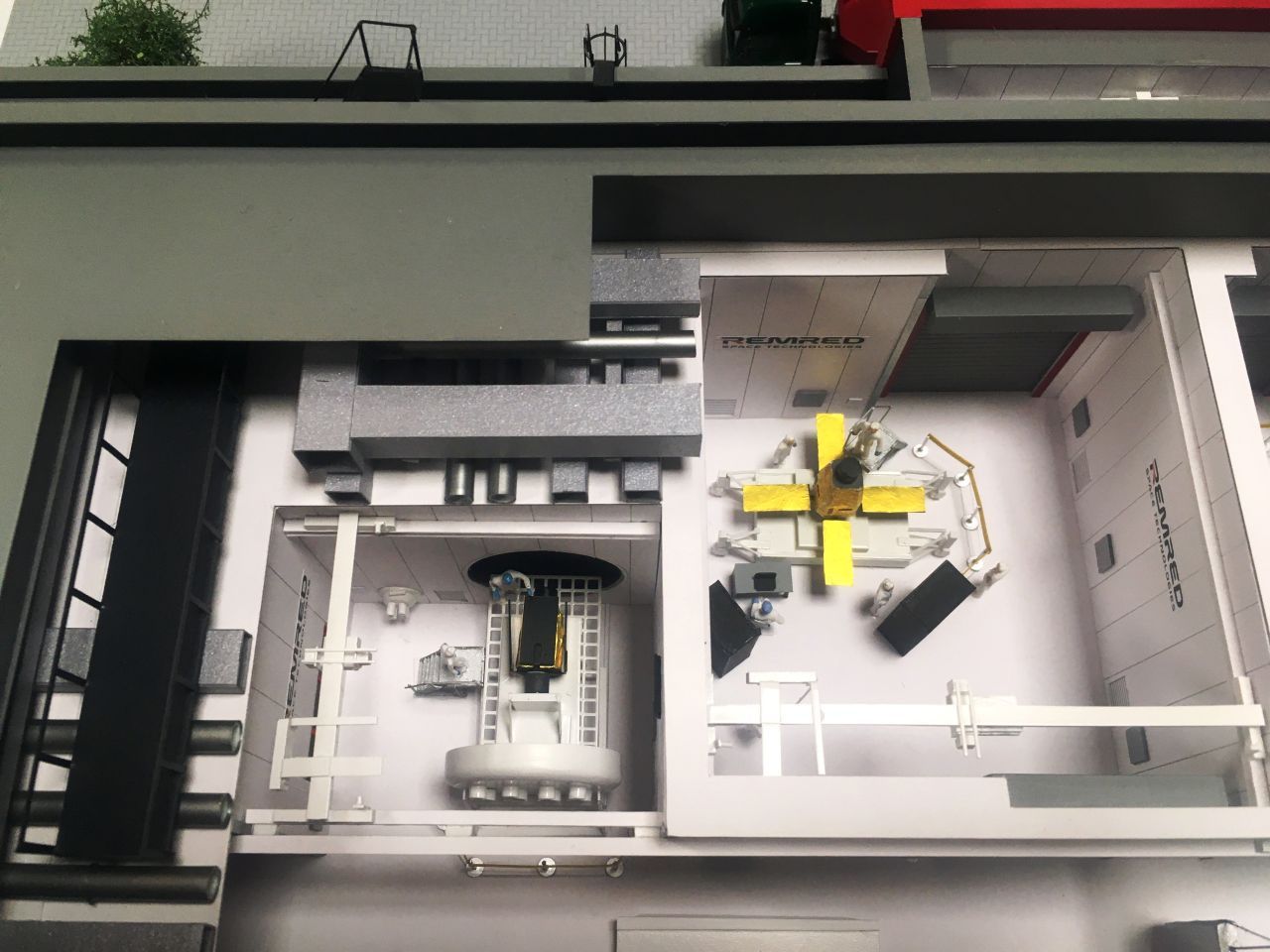

The REMTECH Space Technology Centre

Hungary's largest space MAIT (Manufacturing, Assembly, Integration and Testing) space technology centre is under construction. The REMTECH facility, capable of producing satellites up to 400 kilograms, will employ modular technology for efficient manufacturing, integration, and testing. This greenfield development builds on decades of heritage in space equipment design and MAIT and will significantly extend current capabilities while incorporating state-of-the-art technology solutions in line with global space industry standards.

Get in touch with Remred Space Technologies

Contact us for more information and custom solutions

REMTECH in numbers

Maximum Satellite Manufacturing Capacity

400 kg / 4 x 4 x 4 m³

Building Floor Area

4,000 m2

Clean Room Area

1,500 m2

Laboratory Area

650 m2

Office Area

750 m2

Topping out

April 2024

Foundation

May 2024

Construction

2024 Q2 – 2026 Q3

Operational Solutions

State-of-the-art, optimised, green energy-supported operational solutions

Facility type

Fully automated and modularly configurable ’New Space’ operation

Space Systems

MAIT Services

REMRED offers a wide range of space systems manufacturing, assembly, integration, and testing services, relying on the company’s almost 50 years of relevant heritage and in-house facilities.

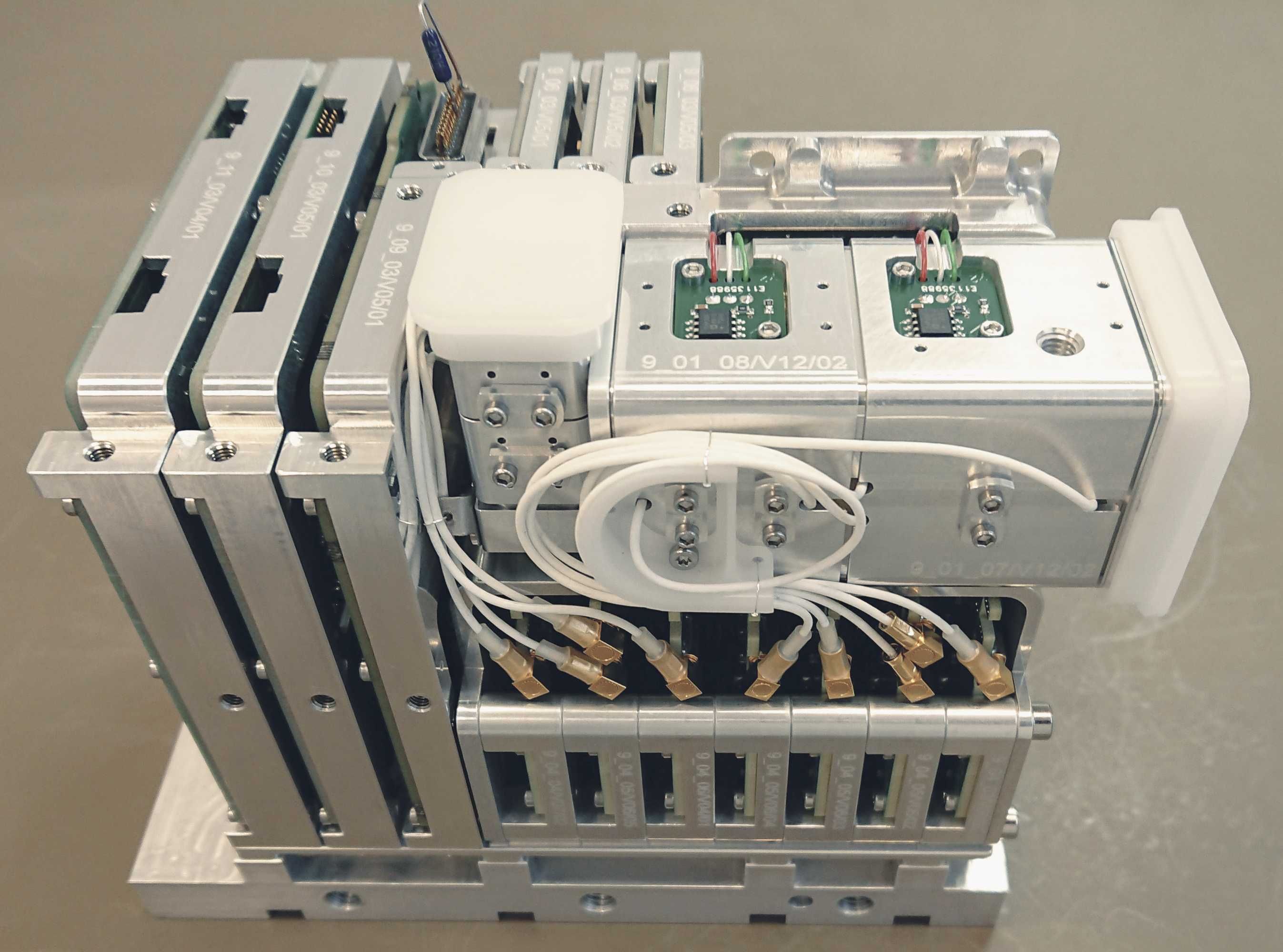

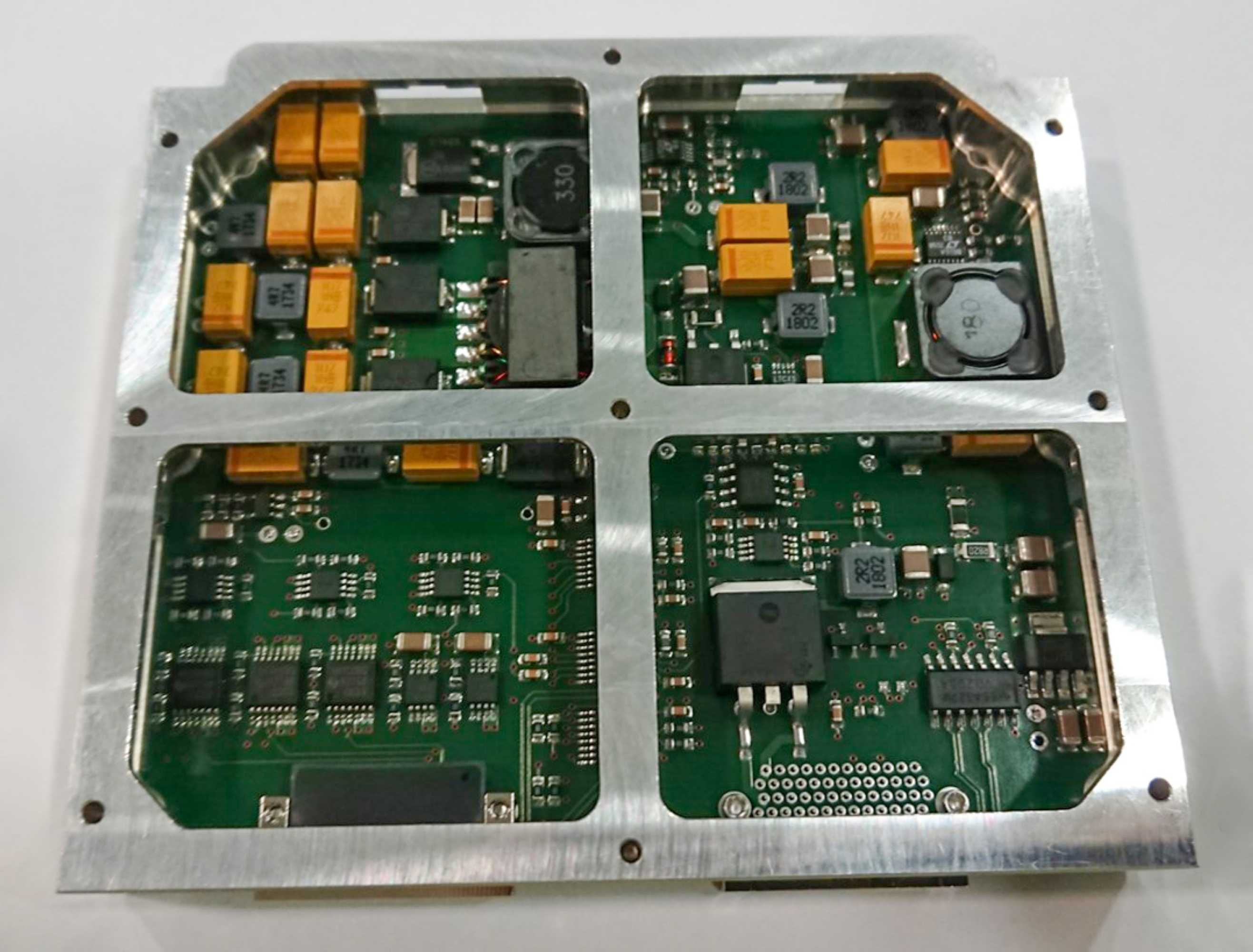

Manufacturing, Assembly & Integration

REMRED Ltd. space systems production portfolio covers the first breadboard models and prototyping until flight model manufacturing under ECSS/IPC standards and all product assurance activities.

ECSS Electrical Assembly Training School

REMRED Ltd. develops an ECSS-compliant, ESA-certified electronics assembly training school.

Mechanical Manufacturing & Repair

REMRED Ltd. offers full service related to high-precision mechanical manufacturing and assembly including CNC milling, 3D printing, and Mechanical inspections.

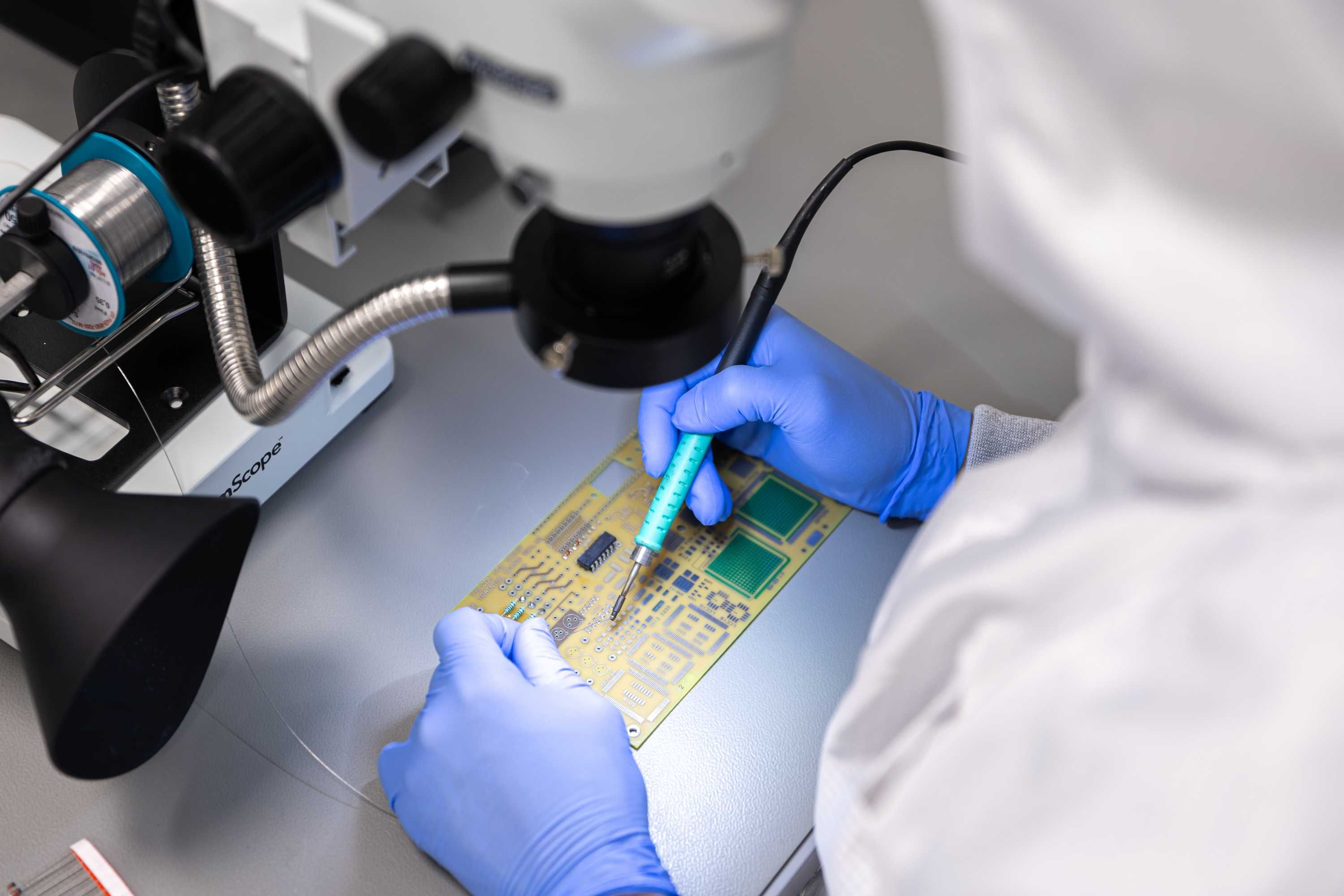

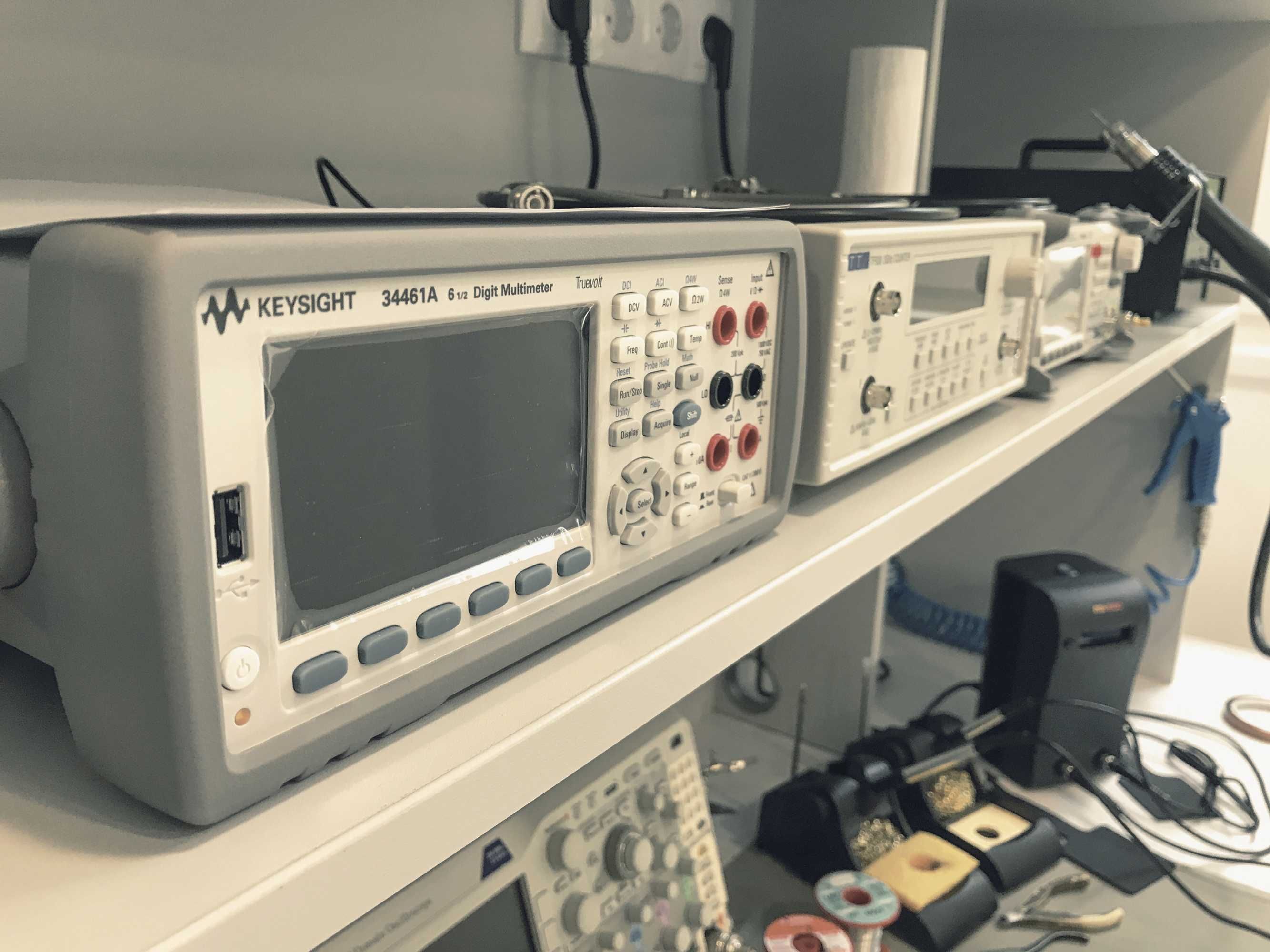

Electrical Manufacturing & Repair

REMRED Ltd. offers full service for electronics and harness (flight) hardware manufacturing and assembly by certified staff according to ECSS/IPC requirements, including PCB procurements, Manual soldering, Automated soldering, PCBA repair/rework, Unit and module assemblies, Harness manufacturing, Wire wrapping, Cable crimping, Optical inspections, Conformal coating, and Unit and system-level board functional testing capabilities.

Space Systems Assembly & Integration

REMRED Ltd. offers ISO9 & ISO8 laboratories, ISO5 optical laboratories, and ISO8 integration halls for space systems procurement inspections, cleaning, preparation, permanent storage, assembly, integration, and all specific activities requiring clean environments.

Thermal-Vacuum Testing

REMRED Ltd. provides space system thermal-vacuum testing services in environmental testing laboratories and cleanrooms, complying with ECSS space industrial standards.

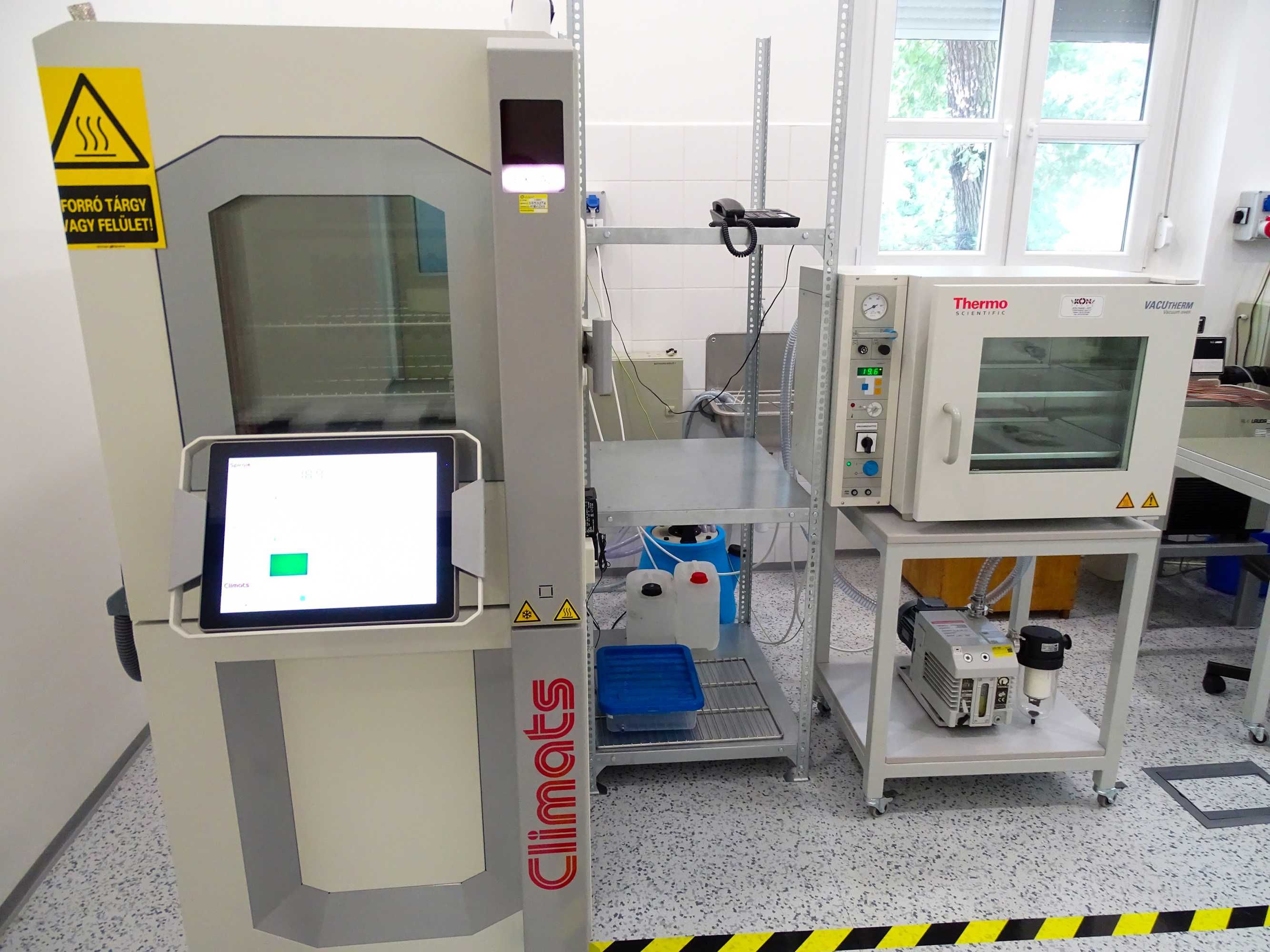

Climate Testing

Humidity testing, thermal cycling and thermal ambient testing in climate test chambers according to ECSS standards. Possibility of combination with vibration testing.

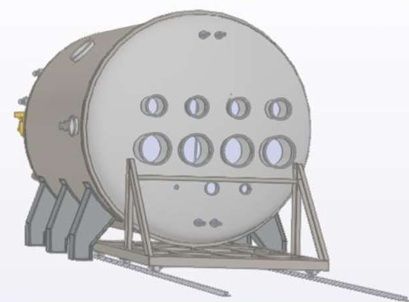

Overpressure Testing

Thermal cycling and thermal ambient testing in an overpressure vessel according to ECSS standards.

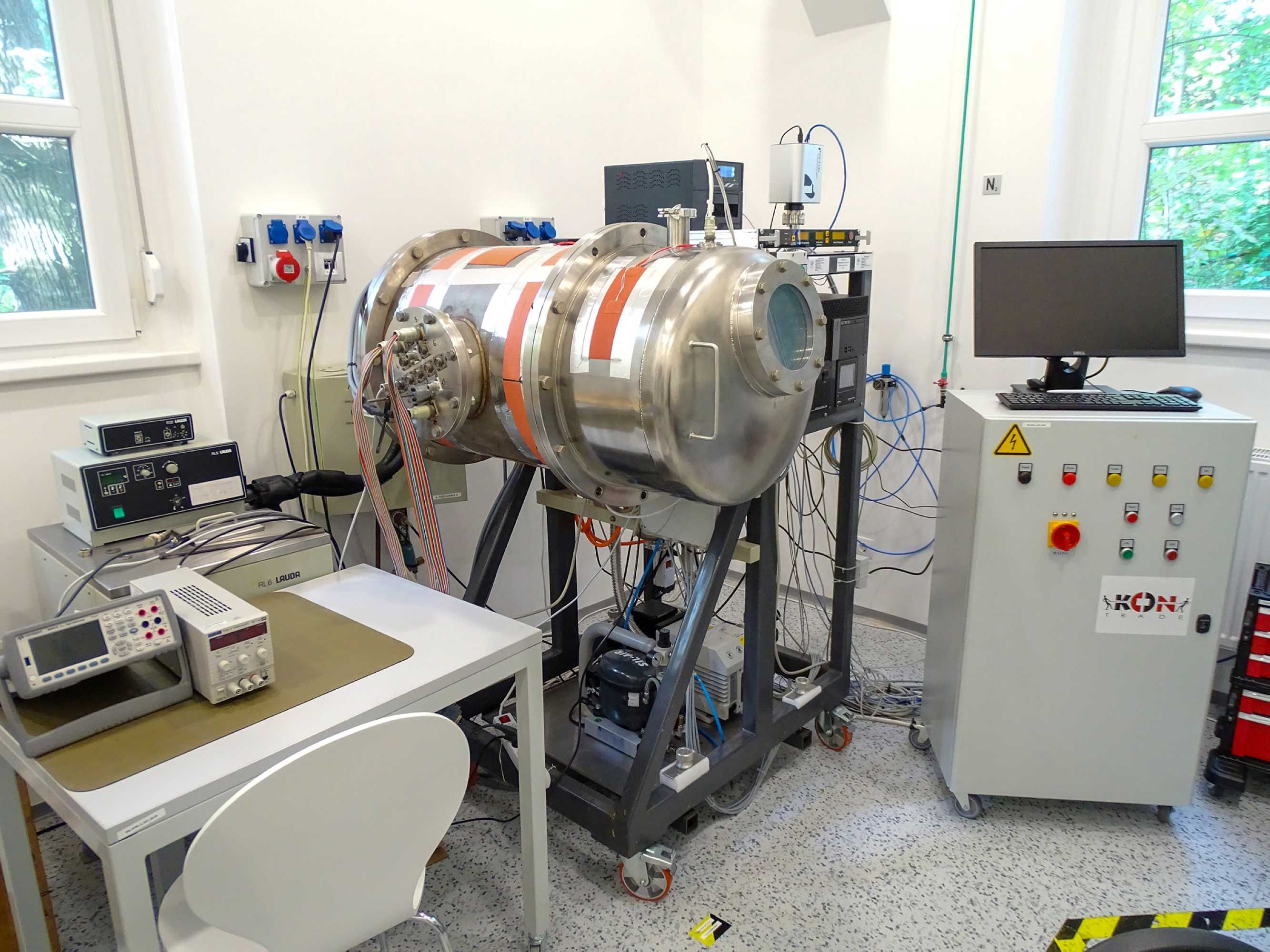

Thermal-Vacuum Testing

Thermal-vacuum (cycling) testing and thermal ambient testing (vacuum) in a thermal-vacuum chamber according to ECSS standards. Test Systems: ’KFKI’ Small TVAC Chamber, ’David’ Small TVAC Chamber, ’Goliath’ Large (55m3) TVAC Chamber.

Bakeout Testing

Vacuum and bakeout testing in thermal-vacuum bakeout chambers according to ECSS standards.

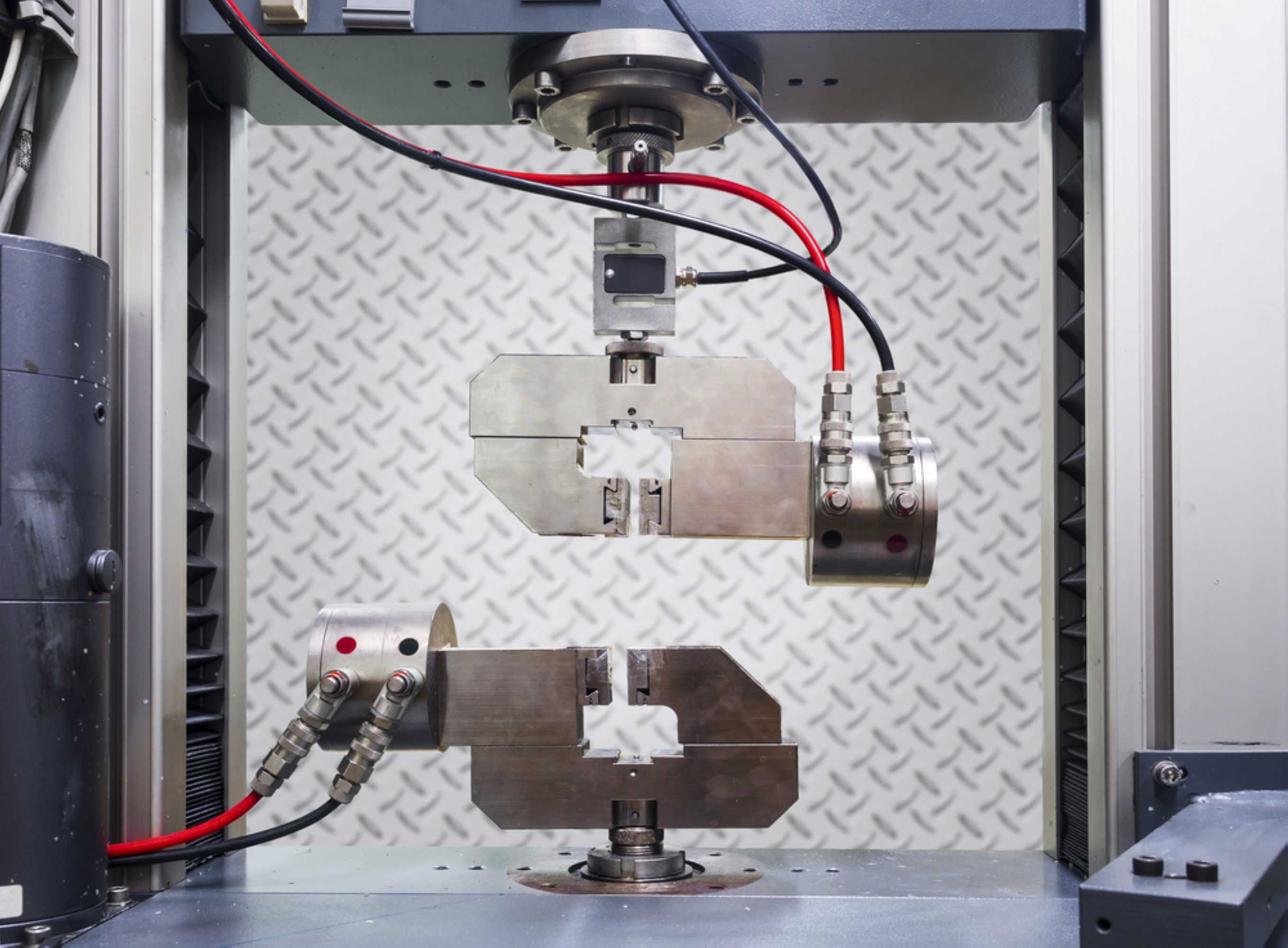

Mechanical Testing

REMRED Ltd. provides space system mechanical testing services in environmental testing laboratories and cleanrooms, complying with ECSS space industrial standards.

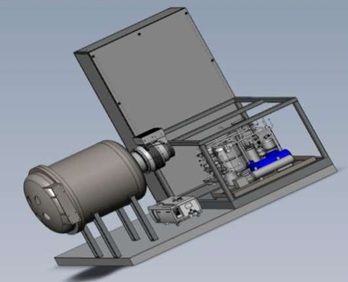

Vibration Testing

REMRED Ltd. offers vibration testing, including resonance search test, sine, and random vibration test, according to ECSS standards. It is possible to combine it with thermal vacuum testing. Test systems: ’KFKI’ Small (40kN) Shaker System, ’Hüperion’ Small (40kN) Shaker System, and’Titan’ Large (200kN) Shaker System.

Mechanical Properties Testing

REMRED Ltd. develops mechanical properties testing capability, including mass, CoG and Mol measurements, according to ECSS standards. Test systems: ’FLASH’ Large (400kg) Mechanical Properties Test System.

Schock Testing

REMRED Ltd. develops shock testing capability according to ECSS standards. Test systems: ’HULK’ Large (10,000g) Shock Test System.

Other Specific Testing

REMRED Ltd. provides space system-specific environmental testing services in applicable testing laboratories and cleanrooms, complying with ECSS space industrial standards.

EMC/EMI Testing

REMRED Ltd. offers EMC/EMI testing services in accordance with ECSS space industrial standards. Test systems: ’BAY ZOLTAN’ EMC test Chamber.

Microbial Testing

REMRED Ltd. offers microbial sampling and testing services in accordance with ECSS space industrial standards for contamination monitoring and control purposes

Acoustic Testing

REMRED Ltd. develops acoustic testing capability in accordance with ECSS standards, using the DEAT technology.

News.

REMRED Ltd.

29-33 Konkoly-Thege Miklos street

H-1121 Budapest,

Hungary